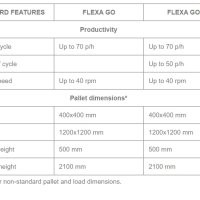

Cyklop - Pieri - Flexa Go - Fully Automatic ring type stretchwrapper

Leírás:

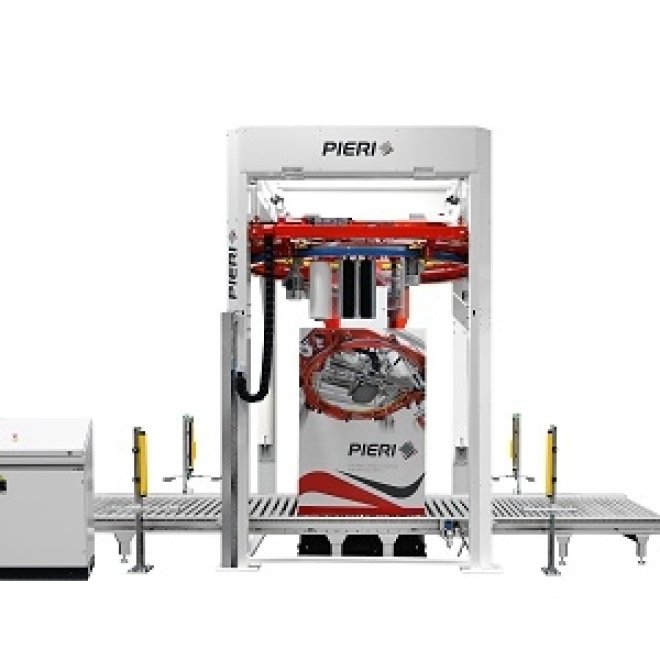

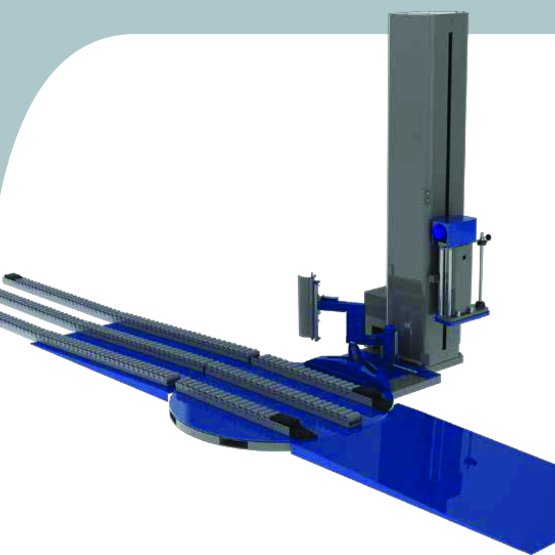

The new FLEXA GO fully automatic ring wrapping machine is the result of 40 years’ experience in the sector.

Offering a perfect balance of flexibility, productivity and quality, FLEXA GO is our solution for customers who want compact size, versatility and efficiency.

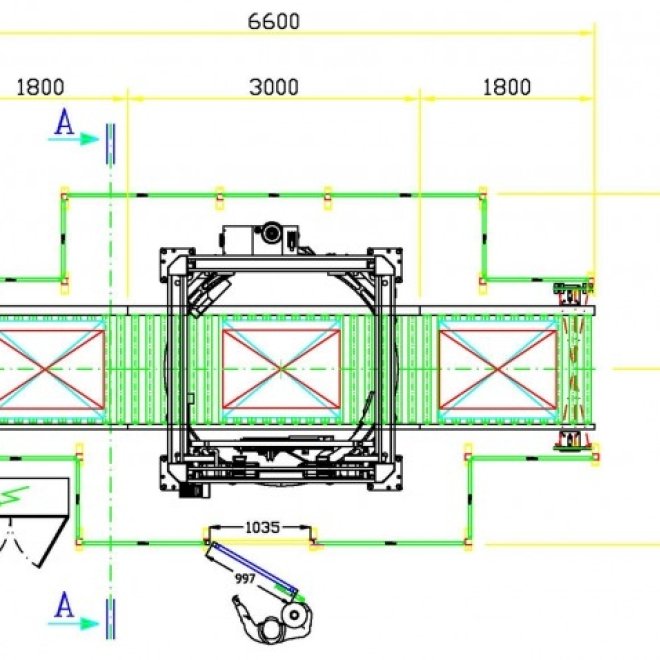

- Compact size: its special design and highly compact frame make it ideal for small footprint.

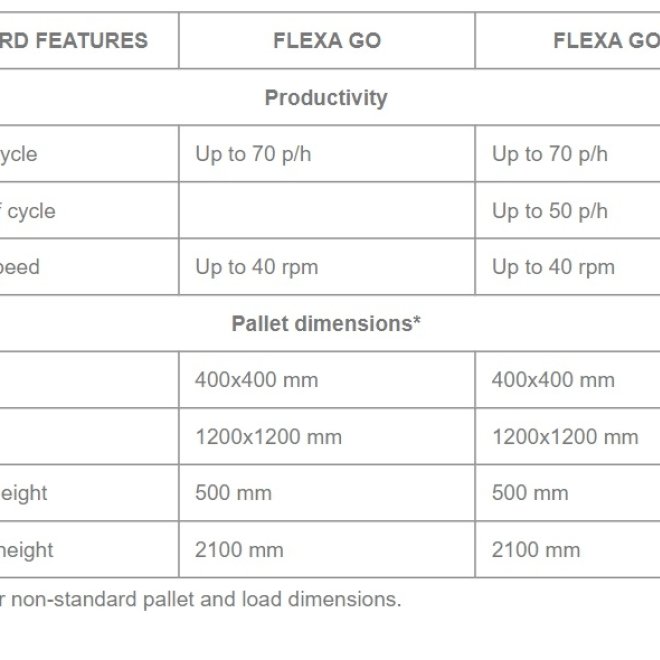

- Versatility: thanks to its new rotating ring technology and the new cutting/welding unit built into the mobile frame, the wrapping cycle can be set to begin and end at any height of the load. FLEXA GO can wrap pallets with dimensions starting from 400 x 400 mm up to a maximum of 1200 x 1200 mm. It can also be installed on conveyor lines with heights from 80 mm and 100 mm.

- Efficiency: FLEXA GO has been designed using the most cutting-edge technical solutions: belts controlled by motors with an inverter guide all the ring movements.

This helps cut maintenance costs and ensures significantly quieter operation. The electronic pre-stretch system guarantees perfect stability and containment of all palletised loads.

Standard features:

- Motorised pre-stretch carriage controlled by an inverter, with pre-stretch with fixed interchangeable ratios. The speed with which the film unwinds is controlled by a sensor which constantly adjusts the motor speed to ensure the pressure exerted on the film is the same over the whole perimeter of the load. The force exerted by the film on the product is electronically controlled and adjusted from the electrical control panel.

- Cutting and welding unit which cuts and welds the stretch film after wrapping. This prevents loose film tails which could cause load stability problems during transportation. This clamping system can be used with any kind of load; the welding unit never comes into contact with the product as it operates against a contrast bar that is then folded away.

Also available the model FLEXA GO TS, fully automatic rotating ring wrapping machine with integrated top sheet applicator. The TS integrated device covers the top of the palletised load with a polyethylene film and is ideal for protecting it against water and dust.

Opciók:

Top press plate

The top press plate exerts pressure on the palletised load to keep it stable during wrapping.

Specially designed for wrapping machine loads, it is available in a pneumatic or electromechanical pantograph version.

Pallet lifter

This device lifts the pallet during wrapping cycle, in this way the film covers both: the load and part or all of the wooden pallet.

Roping device

As the name suggests, the roping system on the carriage reduces the width of the film until a rope is created, increasing load stability and securing the product to the pallet.

In-line top sheet applicator STF203

This automatic device, positioned before the wrapping machine, covers the top of the palletised load with a polyethylene film, protecting it from dust. The film is cold cut by a pneumatically powered blade. The amount of film to place on the load is automatically calculated by a photocell, ensuring optimal consumption.

Electronic pre-stretch carriage with two motors ? mod. PEM-Duo

Electronic spool carriage with variable pre-stretching driven by two motors controlled by an inverter.

The pre-stretch percentage can be set from the electrical control panel (minimum 120% ? maximum 450%) by adjusting the speeds of the motors installed on the carriage separately. This takes full advantage of the characteristics of the film, with a significant reduction in the amount used.

It is also possible to set different pre-stretch percentages for each programme and wrapping cycle, ensuring maximum stability of the palletised load.

Clamping and tucking unit

The ecoMATRIX clamping unit tucks the film tail into the last wrap through a sequence of electropneumatic movements. This sealing system can be used with any kind of film (micro perforated, macro-perforated and standard) and is particularly recommended in lines where there are automatic warehouses, LGVs and/or AGVs.

This device, which does not cut or weld, emits no toxic fumes and is not affected by variations in ambient temperature.

English

English

Magyar

Magyar